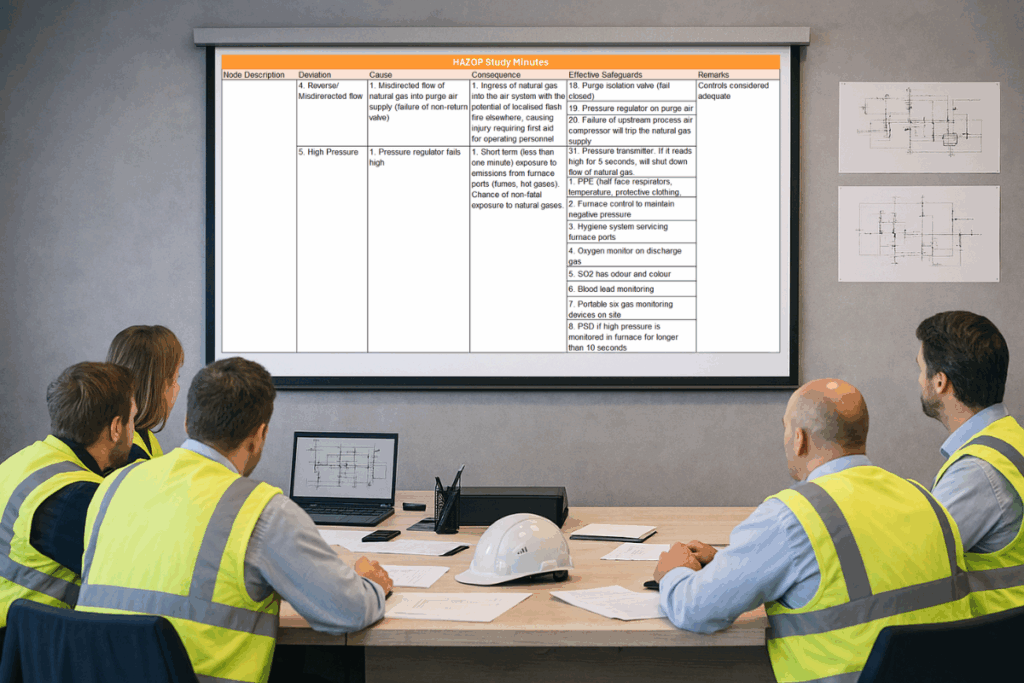

A Hazard and Operability study (HAZOP) is a structured and systematic qualitative technique for identifying and assessing potential hazards and operability concerns with a process design and the proposed method of their control. When done well, a HAZOP produces a comprehensive list of potentially hazardous scenarios and identifies safeguards to manage the risk. However, where a HAZOP is repeated throughout the life cycle of a facility, the identification of significant issues is likely to decrease.

To address this, a ‘Delta HAZOP’ may be conducted instead to maximise the chances of identifying hazards that may be missed during a conventional ‘Re-Do HAZOP’ (i.e. an update to a previously conducted HAZOP). Delta HAZOPs put a greater focus on understanding the creeping changes that have occurred to a process and ensuring that the risks associated with these changes have been understood and addressed.

Some of the items that would typically be reviewed during a Delta HAZOP include:

- Management of change documents

- Site-wide changes

- Staff level changes

- Regulatory, industry or company standard changes

- Procedural changes

- Audit findings

- Near misses and incidents.

In order to utilise the Delta HAZOP process, it is important to have already completed a ‘design stage’ HAZOP and a ‘utilisation stage’ HAZOP that are reflective of the current facility. The IChemE Safety Centre has developed a guidance note on when and how to effectively conduct a Delta HAZOP, which can be accessed here. R4Risk has expert knowledge in conducting HAZOP workshops and is well-equipped to conduct a Delta HAZOP for your facility.

For more information, please contact us.

Go to R4Risk Service Listing: www.r4risk.com.au