Risk Training

R4Risk offers face-to-face training in various aspects of risk management and process safety. Our annual training program covers a range of essential courses, which ensure that attendees are provided with the knowledge and skills to effectively manage their process safety and risk management responsibilities. R4Risk’s trainings are designed to be practical and interactive, as well as providing insight into the wealth of knowledge our trainers have gained from their experience across a vast range of hazardous industry sectors.

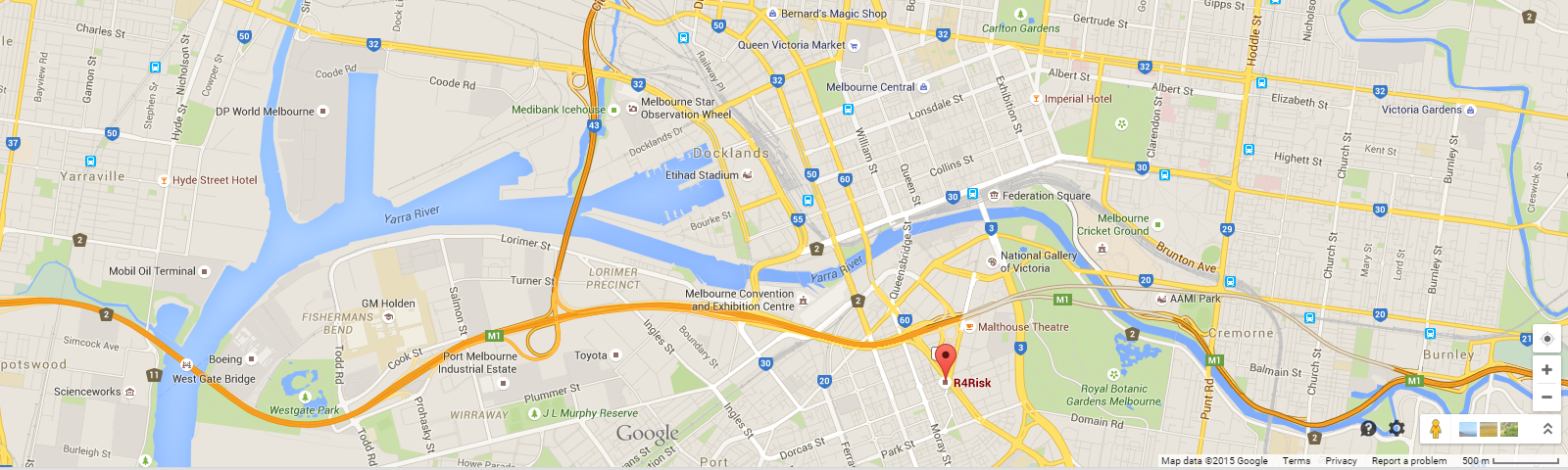

R4Risk’s scheduled face-to-face training is held in Melbourne and is available to anyone who is looking to enhance their skills and understanding of essential process safety and risk management fields. A summary of the training courses available is given below.

Training Program

Introduction to LOPA

One-day course that covers the principles underlying Layers of Protection Analysis and its use in risk management for hazardous events. This includes the identification and assessment of risk management controls and the assessment of control adequacy and risk tolerance.

HAZOP Leader

Two-day course designed to provide participants with the knowledge to facilitate HAZOPs.

Risk Assessment Leader

Two-day course (focused on process industries), designed to provide participants with the knowledge to facilitate HAZID processes.

Introduction to Risk Management

One-day course to educate participants in the principles of identifying, analysing, evaluating, treating and managing the risk of hazardous events.

Trainers’ Profiles

Brian Cooper

Director and Principal Risk Consultant, Brian Cooper has over 30 years’ experience in the high hazard petrochemical manufacturing operations and risk management consulting.

Elio Stocco

Elio is a chemical engineer with over 25 years’ experience in operations and risk management. Earlier in his career, Elio worked with Huntsman Chemicals, Esso Australia, and Johnson Matthey in operational and process safety roles.

Francisco Nazario

R4Risk’s Principal Risk Consultant, Francisco has more than 40 years of experience in process design and risk management.

Richard Rhimes

Richard is a Registered Engineer in Australia and Nigeria; Engineering Executive within Engineers Australia, a Chartered Professional Engineer in Australia and a Certified Safety Professional in the USA.

Brian Cooper

Director and Principal Risk Consultant, Brian Cooper has over 30 years’ experience in the high hazard petrochemical manufacturing operations and risk management consulting. Brian has extensive experience in the application of risk techniques for industrial facilities, having worked for clients across a wide variety of industries, including petroleum, chemical, mining, manufacturing, warehousing and logistics. This includes the preparation of safety cases, incident investigations, land-use planning studies, as well as technical studies such as consequence modelling and fire safety studies.

Brian is an experienced workshop facilitator for hazard identification and risk assessment studies. He has completed many HAZOP, HAZID and LOPA Studies to support Safety Case preparation or general risk reduction initiatives. Examples of facilities and plants Brian has facilitated for are:

- Mining and mineral process coal drying plant

- Petrochemical and gas plants

- Water treatment facilities

- Desalination plants

- Carbon capture plant.

Brian’s technical expertise also include:

- Project management of risk assessments and safety case projects including hazard identification, risk analysis and evaluation,

demonstration of adequacy of risk controls and safety management systems - Extensive experience in the safe storage and handling of flammable and toxic materials

- Process safety management including the identification, prioritisation and implementation of risk reduction improvements

- Significant experience working with planning authorities and regulatory authorities

- Gap analysis for Safety Management System / Major Hazard Facility Safety Case development

- Safety Case development / Audits for Major Hazard Facilities.

Elio Stocco

Elio is a chemical engineer with over 25 years’ experience in operations and risk management. Earlier in his career, Elio worked with Huntsman Chemicals, Esso Australia, and Johnson Matthey in operational and process safety roles. Since 2011, he has been a Director of R4Risk and has extensive experience in the application of various risk assessment methods across a broad range of industries.

Elio is an experienced workshop facilitator for hazard identification and risk assessment studies. Examples of facilities and plants Elio has facilitated for are:

- Gas fired power stations

- Jet Fuel Treater plants

- LPG storage and load-out facilities

- Chemical and petrochemical facilities

- Petroleum refineries

- Water treatment plants

- Gas to liquids plant.

He is also an experienced HAZOP leader and has delivered HAZOP leader training for companies such as BlueScope Steel and Shell.

Elio’s technical expertise also includes:

- Development of Safety Cases for Major Hazard Facilities

- Project management of risk assessments and Safety Case projects, including hazard identification, risk analysis and evaluation, demonstration of adequacy of controls and safety management systems

- Process safety management including the identification, prioritisation and implementation of risk reduction improvements

- Consequence modelling

- Safe storage and handling of dangerous goods

- Emergency response planning

- Risk controls adequacy assessment and auditing

- Audits of Safety Management Systems

- Incident investigations

Francisco Nazario

R4Risk’s Principal Risk Consultant, Francisco has more than 40 years of experience in process design and risk management. Over this time, he has worked extensively within ExxonMobil, specifically in risk and process safety. His experience includes:

- Performing process safety management audits for oil refineries

- Performing HAZOP reviews of new and existing oil refining and chemicals processing facilities in countries such as the US, Argentina, France and Singapore

- Analysis of incidents such as fires and explosions in furnaces, piping, tanks and high-pressure process units to identify root causes

- Reviewing the adequacy of internal ExxonMobil process safety standards and proposing updates to these standards to address identified issues

- Developing ExxonMobil guidelines for the sizing of pressure relief valves in flashing service

- Developing and updating internal ExxonMobil process safety standards and procedures for the evaluation of overpressure protection and pressure relief system design.

Francisco also has a wide range of experience in the application of various risk assessment methodologies in a variety of industries. Examples of industries he has worked in are:

- Petroleum refining

- Chemicals manufacturing

- Oil and gas processing.

Francisco is an experienced facilitator of HAZOP and LOPA studies. He has also managed the development and submission to the regulator of safety cases for major refineries. His technical expertise also includes:

- Fire Safety Studies

- Quantitative Risk Assessments (QRA)

- Consequence modelling of toxic, fire and explosion hazards

- Overpressure protection analysis

- Vapour cloud explosion evaluation

- Emergency shutdown systems.

Richard Rhimes

Richard is a Registered Engineer in Australia and Nigeria; Engineering Executive within Engineers Australia, a Chartered Professional Engineer in Australia and a Certified Safety Professional in the USA. Richard has over 40 years of engineering and management experience. During this time, he has worked in four continents in a variety of engineering, operating, management, technical safety and environment, health and safety roles.

Richard was based in Lagos, Nigeria, with DeltaAfrik Engineering Limited as its Head of Loss Prevention Engineering. His assignments were for Nigerian subsidiaries of Shell, Chevron, Total and ExxonMobil. Prior to this, he was the General Manager Quality and Risk for Qantas and spent over 30 years in the oil and gas industry, based in Australia and the US, with responsibilities covering Australia, New Zealand, Asia Pacific, USA, SE Africa, parts of Europe.

Richard has facilitated over 300 hazard and risk assessments. Examples of facilities and plants he has facilitated include:

- Refineries

- Oil and gas terminals

- Shipping and aviation operations

- Steel plants.

Richard’s technical expertise also include:

- Consequence analysis

- Causal factor and root cause analysis

- Qualitative and semi-qualitative risk assessment

- Quantitative risk assessments

- Safety cases

- Loss prevention reviews and audits

- Environment, Health and Safety (EHS) reviews and audits

- Disaster and emergency planning

- Design safety reviews

- Human factor reviews

- Fire protection systems

- Quality Management Plans

- Operations management of MHF sites.

Training Enquires

Training Enquires For training enquiries, please email [email protected].