Hydrogen is rapidly gaining attention in the energy industry as a cleaner, more sustainable solution. Its potential to decarbonise sectors such as transport, power generation and industrial processes makes it a key player in the global energy transition. However, hydrogen presents unique hazards that must be managed effectively to ensure safety.

Understanding the Hazards of Hydrogen

Hydrogen has long been part of industrial processes, but its application in clean energy is accelerating. Many organisations entering the hydrogen space bring expertise from transport or mechanical disciplines, yet limited exposure to hazardous chemicals can leave knowledge gaps in managing hydrogen’s risks.

Key hazards include:

- Small molecular size – hydrogen can leak through tiny gaps, increasing the likelihood of undetected releases.

- Wide flammable range – hydrogen can burn at very low concentrations and remains flammable up to very high concentrations, making ignition risks harder to eliminate.

- Easily ignited – hydrogen has a very low ignition energy – about an order of magnitude less than for other common fuels. This means that hydrogen can be ignited by very small sparks, making ignition sources like static electricity a major safety concern.

- Invisible flame – a pure hydrogen flame can be almost invisible during daytime, making it hard to detect.

- Incident escalation – Hydrogen incidents can escalate, igniting nearby flammable or combustible inventories and causing cascading failures.

These characteristics demand a robust approach to Process Safety Management (PSM).

What is Process Safety Management for Hydrogen?

PSM is a systematic approach to prevent and mitigate catastrophic incidents. This includes:

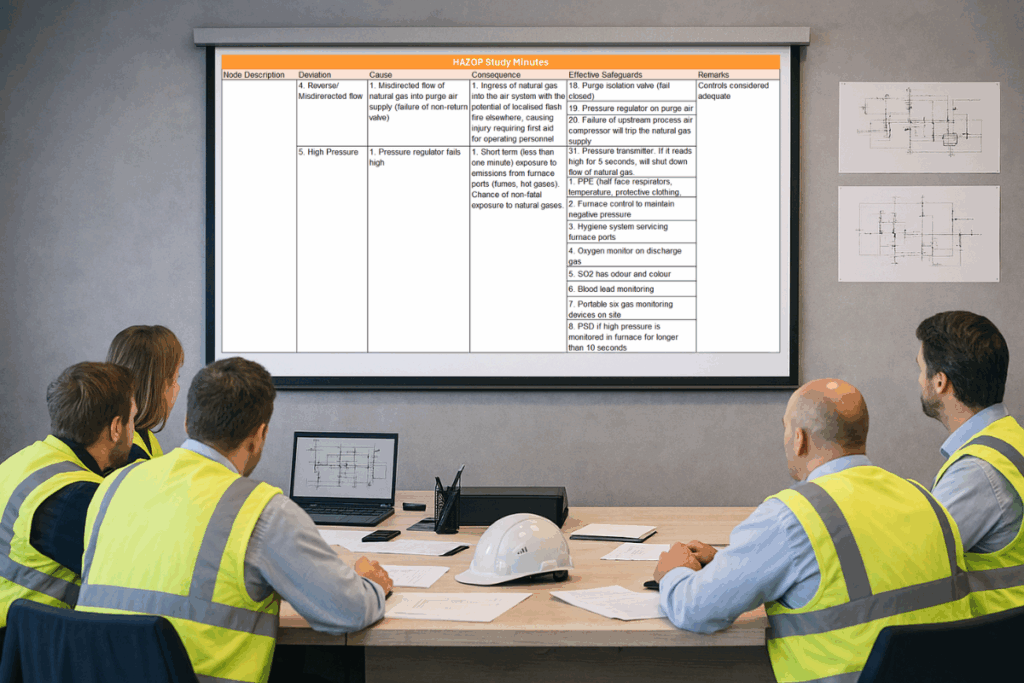

- Hazard identification and risk assessment – systematically identifying hazards and implementing robust engineering and administrative controls.

- Consequence modelling – understanding the potential size and impact of a release, fire or explosion.

- Facility layout – ensuring that the layout of the facility minimises the potential for exposure of vulnerable equipment and the resulting incident escalation.

- Safety management systems – embedding strong systems of work to maintain safety throughout the facility’s lifecycle, that includes:

- Permit-to-work systems

- Management of change

- Operating procedures

- Maintenance strategies

- Training

- Operational readiness

- Emergency response planning

- Assurance and review processes.

Why it Matters?

As hydrogen adoption accelerates, integrating Process Safety Management, from the earliest design stages through to ongoing operations, is critical for protecting people, assets and reputation. The consequences of a hydrogen incident can be far-reaching, regardless of how unlikely it may seem. Effective systems ensure that hazards are identified, and their risks controlled and continuously managed.

Looking to Improve Safety Across Your Hydrogen Operations?

R4Risk has extensive experience in Process Safety Management across many industries, including extensive hydrogen applications. From consequence modelling to hazard studies and safety management systems, we can provide solutions tailored to your facility’s needs.

If you want to know more about process safety management for hydrogen, check out our full range of services here, or contact us directly.