Australia’s first National Climate Risk Assessment, released in October of this year, confirms what many already know: climate change is increasing the frequency and severity of extreme weather events. Rising sea levels, longer heatwaves, worsening droughts and more frequent floods are just some of the direct impacts Australians can expect.

These hazards are already affecting Australians and the report highlights that they are likely to occur more often, with greater intensity and sometimes simultaneously. This creates the potential for cascading impacts across industries, communities, supply chains and critical services. For process safety management, this means considering not just individual hazards, but also the potential for multiple, compounding events – especially in remote or vulnerable areas where response capacity is limited.

The assessment also points to broader risks, including disruptions to energy supply, transport routes, water quality and emergency response. As climate risks grow, managing process safety becomes more complex and more important than ever.

The Changing Climate and Process Safety

Climate change is introducing new and evolving risks to process safety.

For rural or regional locations, bushfires and smoke threaten facilities and disrupt operations. Floods, cyclones and heavy rainfall may damage infrastructure, cause chemical releases and overwhelm containment systems. The 2017 Arkema incident in Texas, where flooding led to chemical fires, is a reminder of how climate-driven events can escalate into major process safety incidents. Severe storms and high winds can lead to structural failures or power outages and rising sea levels put coastal facilities at greater risk.

Australia’s long, remote transport routes also mean that climate impacts can disrupt supply chains, making it essential for organisations to adapt their process safety strategies to these changing conditions.

Adapting Process Safety Systems for Climate Hazards

To effectively manage these evolving risks, organisations can take several proactive steps:

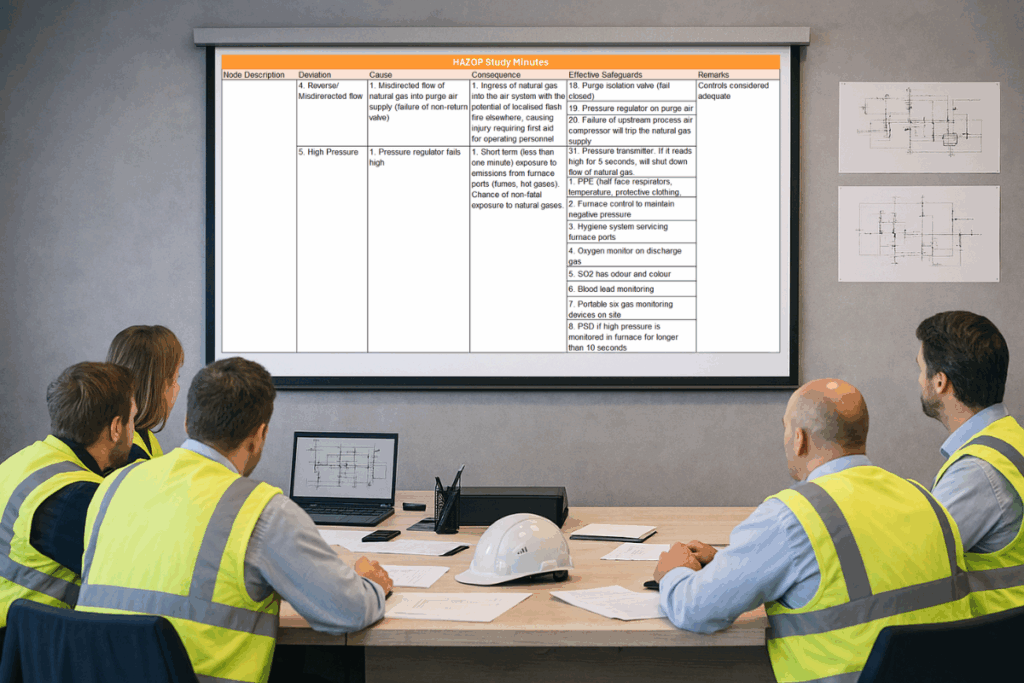

- Integrate climate-related hazards into process safety management by incorporating them into hazard identification, risk assessments and emergency planning

- Design and operate for variability, ensuring that processes and infrastructure can withstand more severe and unpredictable environmental conditions or disruptions to resource supply.

- Regularly review and strengthen safeguards, introducing new measures as climate risks change and updating maintenance and inspection routines

- Strengthen emergency preparedness by developing and testing response plans for severe weather and climate-related events, ensuring staff are trained in these procedures and coordinating with local authorities and emergency services for an effective response.

How Process Safety Frameworks Mitigate Climate Risk

A robust process safety framework helps organisations systematically identify, assess, and control climate-related hazards. This approach enables businesses to:

- Identify site-specific vulnerabilities to climate hazards (e.g. flood-prone areas, heat sensitive equipment)

- Prioritise risk reduction measures as climate risks evolve, including infrastructure upgrades or additional controls

- Support compliance with Australian regulations and adaptation planning, including emerging requirements for climate risk reporting and reducing emissions.

Looking Ahead

As Australia’s climate continues to change, process safety will play a critical role in protecting people, assets and the environment. Proactive risk management, ongoing adaptation and a strong safety culture are essential for building resilience in the face of new and evolving hazards.

Need help integrating climate risk into your process safety management? R4Risk helps organisations to identify climate-related hazards – including common cause failures from extreme weather – and ensures controls remain effective under climate stress. Get in touch to learn more.