Over the past year with R4Risk, Lead Risk Engineer Simon Reveley has brought his wealth of previous experience to HAZOP studies across diverse industries.

Simon’s top tips for a successful HAZOP include:

Before the HAZOP:

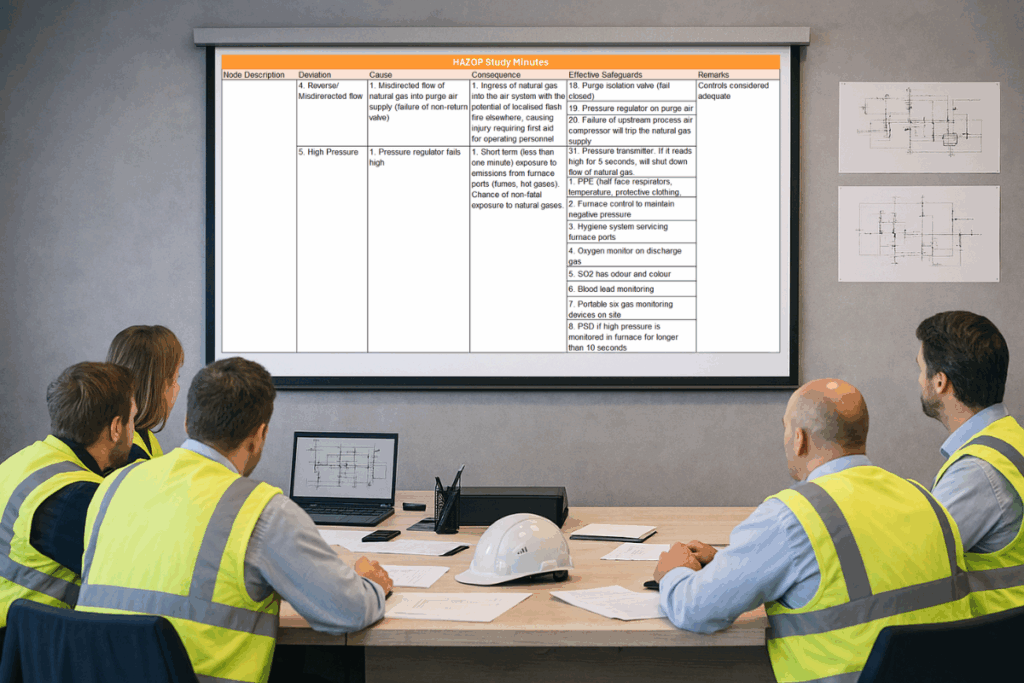

➤ Documentation is critical. It’s essential that the team has access to all relevant information such as P&IDs, process data, design details, and operational insights before the session begins.

➤ Pre-populate causes & consequences – carefully. It can be a great headstart, but only if you truly understand the process (and the quality of any prior study). Accept that this will result in a degree of over-preparation, Deleting is almost always faster than generating from scratch, which saves time during the study. Never pre-populate controls or recommendations. If pre-populating from a similar study, ensure you use the same nodes and study them in the same order.

➤ Study start-up and shutdown as nodes, using batch keywords. A significant fraction of accidents occur during these transitions.

➤ Use an ‘overview’ node. This is an excellent tool for covering things like the provision of safety showers, spill kits, PPE and other things adjacent to the process, so nothing falls through the cracks.

➤ Preference is to have everyone in the room: use remote and hybrid wisely. Having the whole group in a room is still the best technique, but remote and hybrid are valid options, especially given the travel times/distances common in Australia!

➤ Have the right team, and have them prepared. Each member should bring suitable experience and expertise to the table, as this diversity of knowledge is what enables the team to identify hazards comprehensively and propose practical safeguards. Having said that, I’ve found it more common recently to have too many people instead of too few.

➤ Walk the plant beforehand. A site walk-through pays dividends in study quality.

During the HAZOP:

➤ Consider starting with the “heart” of the process. If upstream processes are relatively simple, you can consider beginning with the more hazardous nodes while energy and attention levels are higher – even if this does mean occassionally working back from causes at a node boundary to more specific causes in an upstream utility node.

➤ Review actions at the end of each day. I’ve been doing this for a few years now and consider it essential. It allows the team to assess the action wording and determine if it needs refinement, particularly if it needs more context to be fully standalone.

It also moves action allocation out of the main flow of the day and enables a near-immediate draft of actions post-study. Being able to issue a first version of the actions quickly lets people progress the design before the full report is issued.

➤ Use decisive phrasing in recommendations. Swap “consider” for “or demonstrate this is not required” to drive clearer outcomes (e.g., install a relief valve… or demonstrate that this is not required“). You can also link closure to the issue of a deliverable: ‘consider the installation of a relief valve, close this action by issue of meeting minutes or similar.

After the HAZOP:

➤ Don’t be afraid to add more context to recommendations. Additional text in the recommendations should be clearly marked to differentiate it from the text reviewed by the team and should focus on the hazardous situation the recommendation is addressing. Frequently the HAZOP recommendations will go into a live document for tracking to closeout, separate from the report.

Bottom line: Thoughtful preparation, clear language, disciplined action reviews and on-site context turn HAZOPs into a high value hazard identification exercise.