Our Services

Hazard Identification (HAZID)

Expert HAZOP Facilitation Services

Enhancing Safety Through HAZOP Studies

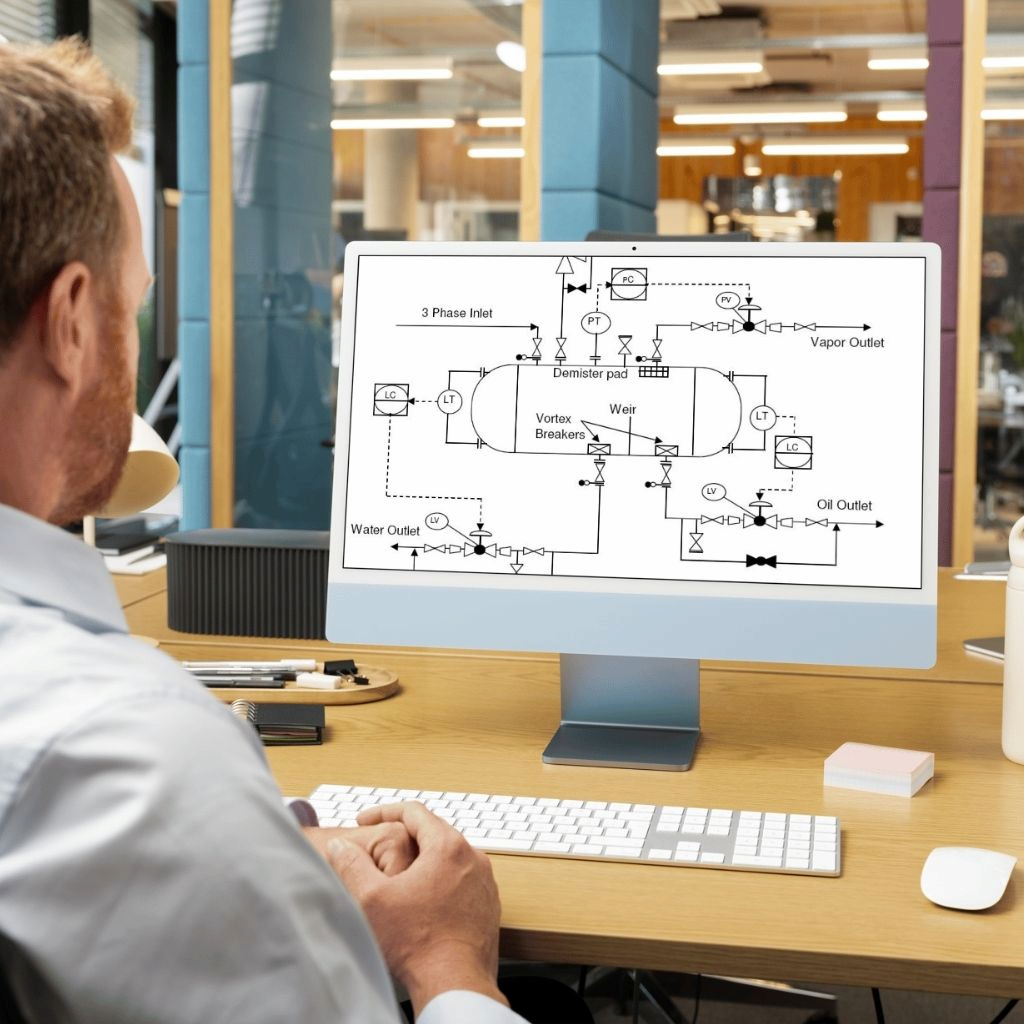

A Hazard and Operability (HAZOP) study is a structured workshop that identifies potential safety hazards and operational concerns in process designs. It brings together a multidisciplinary team to systematically assess project risks by reviewing design segments (“nodes”) using guide words to prompt credible deviations from the design intent.

HAZOP studies are typically undertaken during the design or modification of a facility, allowing safety improvements to be integrated before operations commence. By identifying risks early, HAZOP supports the implementation of safe, compliant operations aligned with industry best practice.

Key benefits of conducting a HAZOP study include:

- Identifying design flaws and risks before they escalate

- Confirming compliance with safety regulations, industry codes and standards

- Minimising operational disruptions and costly incidents

- Reinforcing safety culture across engineering and operations teams.

HAZOP Studies for Process Safety

HAZOP: A Proven Systematic Approach

R4Risk’s HAZOP facilitators are chartered engineers with experience across industries such as chemical, pharmaceutical, mining, nuclear, logistics, aerospace and oil & gas. Their independent facilitation ensures each HAZOP study is conducted efficiently and thoroughly, delivering considered, actionable recommendations, supporting safe, compliant and operable designs.

The outcomes of a HAZOP include:

- Identification and correction of potential deviations from the design intent of the system

- Identification of process and equipment hazards and operability issues, their causes and existing safeguards

- Recommendation of additional risk reduction measures to eliminate, prevent or mitigate the identified hazards

Where the consequences of deviations may generate a hazard or operability issue, the study team would make recommendations to address the issue.

The guideword approach is highly adaptable and can be applied across a variety of systems, including:

- New / existing process plants

- Plant modifications

- Batch operations

- Materials handling operations

- Construction / demolition works.

FAQs on HAZOP

Frequently Asked Questions

While we typically find that a better outcome is reached with the team face-to-face in one location, we have ran plenty of workshops virtually. This can be a more time efficient option where multiple people are based in different locations.

Yes, R4Risk can host your HAZOP workshop from our South Melbourne office. Contact us for further information.

As part of R4Risk’s HAZOP services, a technical secretary (scribe) and software can be provided to record the HAZOP minutes. All of R4Risk’s scribes are qualified risk engineers.

A successful HAZOP depends heavily on the make-up of the workshop team. It is the responsibility of the client to ensure that the make-up of the HAZOP team is suitable. This should include appropriate representation from the equipment designers, process, safety, operational and maintenance personnel.

Expert HAZOP Training Courses Offered

Related Training Courses

Upskill with R4Risk

HAZOP Leader Training

R4Risk’s HAZOP Leader training provides participants with the knowledge to facilitate HAZOPs. It's designed for experienced HAZOP team members who are in, or moving into, JAZOP Leader roles